Are you losing efficiency without realizing it?

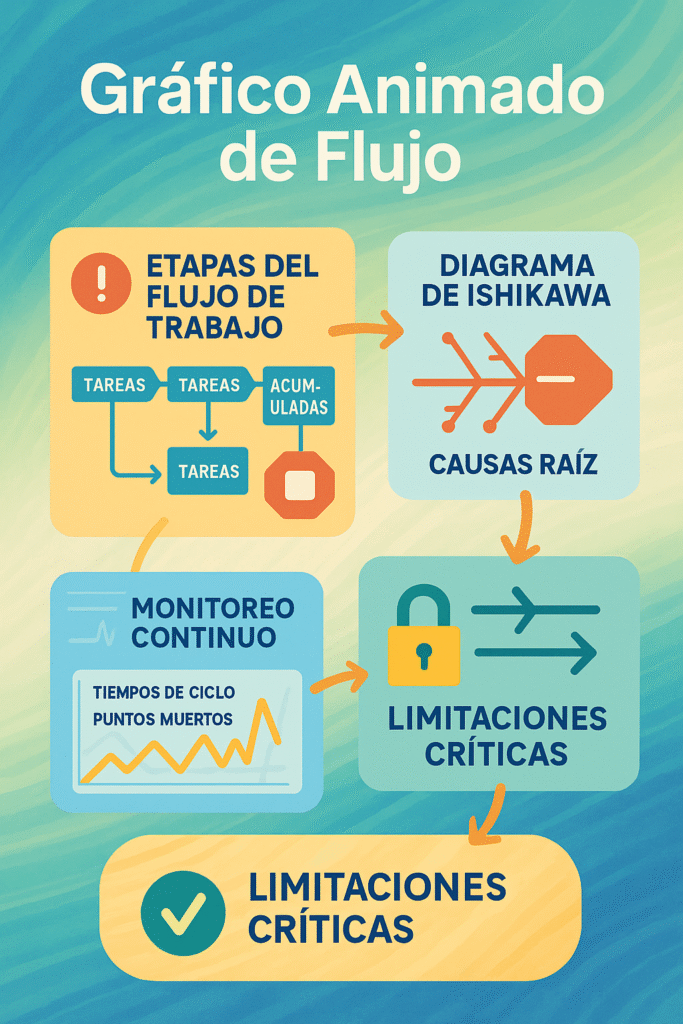

Flow mapping: Create a diagram to visualize where tasks accumulate.

Root cause analysis: Use an Ishikawa diagram and ask “why?” until you find the root cause.

Continuous monitoring: measures cycle times and detects dead spots.

Critical Limitations: Identify components that, although small, hold back the entire system.

Resource review: Check for shortages of personnel, materials, or infrastructure.

Bottlenecks can increase your production times by 20% to 50%.

Do you want to discover if there are invisible blockages in your processes?

#OperationalEfficiency #EvolutionaryArchitecture #ProcessOptimization